RISKS EXPLAINED

Call us today on 0456 813 864 or email admin@racksafe.com.au

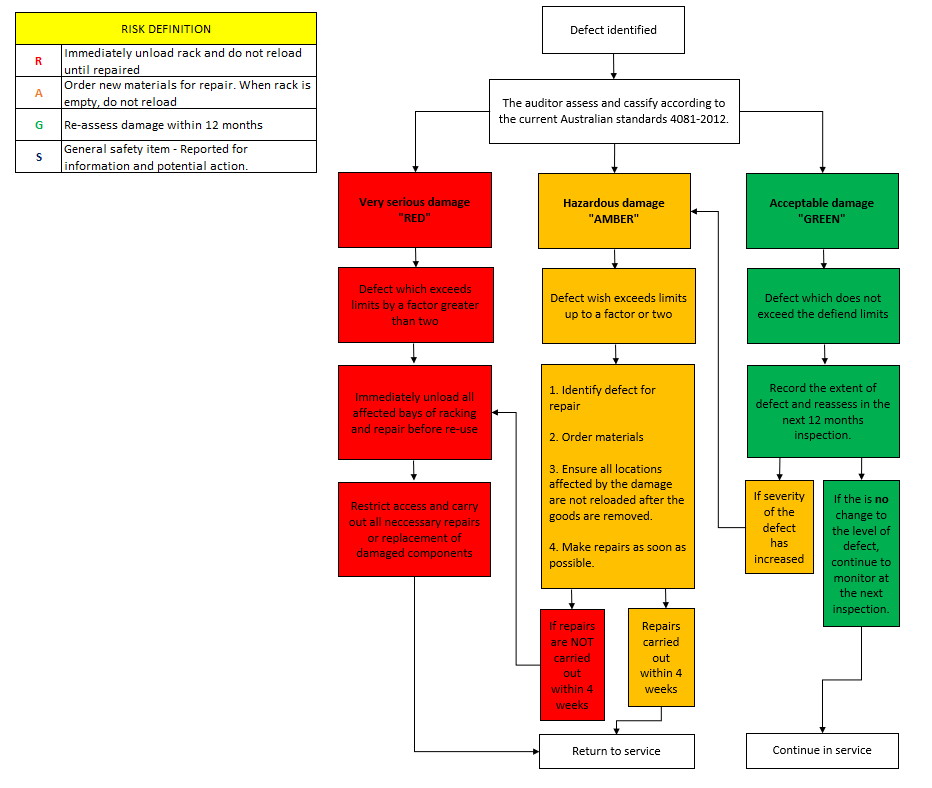

Let's talk about the risk matrix

Pallet racking is a critical component of warehouse storage systems, and safety is of paramount importance to prevent damage to the goods, the racking, and, most importantly, the workers. One of the tools used to assess the risk of pallet racking is the risk matrix.

The risk matrix operates on a dynamic duo of intersecting factors: the probability of a risk event occurring and the consequential impact it may have on the business.

This tool facilitates the visualization of the probability versus the severity of a potential risk, thereby assisting in categorizing risks into high (red), moderate (amber), or low (green) risk categories.

As an integral part of the risk management process, RackSAFE utilizes the risk matrix to prioritize risks and formulate an effective mitigation strategy for our clients.